InsidetheWorldofElectronicsManufacturing:AnIn-DepthLook(电子工厂英语)

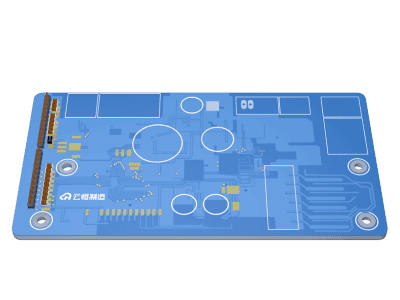

Deep within the heart of an electronics factory, the assembly line stands as a testament to precision and efficiency. Over the years, these production lines have transformed from labor-intensive manual processes to highly automated systems, significantly minimizing human error. Today, robotic arms gracefully perform tasks like soldering circuits, while conveyor belts seamlessly transport components from one station to another. This evolution not only boosts productivity but also enhances product consistency, setting new benchmarks in quality control.

Technological Innovations in Electronics Manufacturing

At the forefront of manufacturing innovation, electronics factories are embracing cutting-edge technologies. The widespread adoption of automation sees machines programmed to execute complex tasks previously done by humans. Advanced computer numerical control (CNC) machines carve intricate patterns into circuit boards with unparalleled precision. Furthermore, the integration of artificial intelligence and machine learning algorithms enables predictive maintenance, minimizing downtime and maximizing operational efficiency. These technological advancements are revolutionizing the production of electronic products.

Sustainability in Electronics Manufacturing

Environmental consciousness is deeply ingrained in modern electronics manufacturing. Factories are increasingly adopting sustainable practices, such as using recycled materials and implementing lean manufacturing principles to minimize waste. Energy-efficient lighting and power systems help reduce the carbon footprint, while rigorous recycling programs ensure obsolete or defective components are responsibly repurposed. The industry's commitment to sustainability is reflected in its efforts to create eco-friendly products that align with global environmental standards.

Quality Assurance in Electronics Manufacturing

Maintaining high-quality standards is paramount in electronics manufacturing. Rigorous testing protocols are implemented at every stage of production, guaranteeing flawless functionality of each device before reaching consumers. From initial design validation to post-production audits, quality assurance teams utilize advanced diagnostic tools to diligently inspect components and final products. This dedication to excellence ensures that electronic devices meet both industry norms and customer expectations.

Global Connectivity in Electronics Manufacturing

The electronics manufacturing industry is inherently global, with supply chains spanning across continents. Collaboration and communication technologies play a critical role in coordinating efforts between distant factories and headquarters. Real-time data sharing and cloud-based infrastructure facilitate seamless integration of operations, enabling quick responses to market changes or supply chain disruptions. This interconnectedness fosters a cohesive approach to manufacturing that transcends geographical barriers.

Workforce Development in Electronics Manufacturing

Investing in workforce development is critical for the continued success of electronics manufacturing. Tailored training programs ensure that employees are equipped with both technical and soft skills to handle the demands of their roles. As the sector evolves, there is a growing emphasis on upskilling and reskilling workers to adapt to new technologies and methodologies. By nurturing a knowledgeable and versatile workforce, factories can remain competitive in an ever-changing industry landscape.

Safety and Ergonomics in Electronics Manufacturing

The safety and well-being of employees is a top priority in electronics manufacturing facilities. Strict safety protocols and ergonomic workplace designs minimize the risk of injuries and long-term health issues. Automated processes reduce the need for manual labor in hazardous environments, while comprehensive training programs educate workers on safe practices. These measures not only fulfill legal obligations but also reflect a commitment to protecting the most valuable resource in any factory - its people.